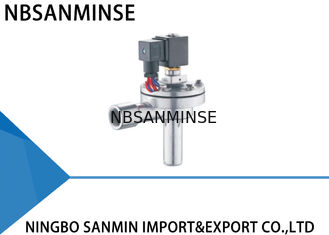

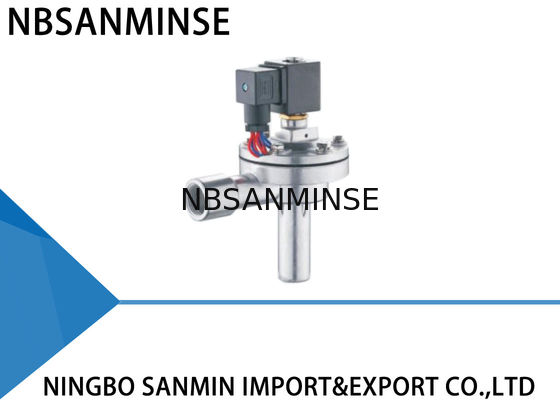

QG-Z-20A Series Pneumatic Pulse Valve Right Angle Type 220VAC / 24VDC / 110VAC GOYEN Type

Technical Parameter

|

Right angle |

Embedded |

Inline |

Plug |

| Design-pressure |

0.3~0.8MPa |

0.2~0.8MPa |

0.3~0.8MPa |

0.2~1.0MPa |

| Working-pressure |

0.3~0.6MPa |

0.2~0.6MPa |

0.3~0.6MPa |

0.2~0.6MPa |

| Ambient Temperature |

-25~60℃ Customized for lower or higher temperature |

| Relative Humidity |

≤85% |

| Working Medium |

Clean Air |

| Voltage |

AC220V/DC24V/AC110V/AC24V Customized |

| Protection Class |

IP65 |

| Diaphragm Life |

Over One Million Cycles |

| Cv/Kv |

Call us for detail |

Body : ADC12 die cast

Armature : 430 FR stainless steel

Diaphragm : Nitrile or Viton

Spring : 321 stainless steel

Fasteners : 302 stainless steel

Good quality membranes shall be selected and used for all the valves , with each part checked in each manufacturing procedure , and put into the assembly ling conforming to all the procedures . Every finished valve shall be taken the electriferous blowing test .

During installation and commissioning

Failure phenomena

1 . The valves cannot all be opened, but the leading part does act.

2 . Some valves do not work, but the others are normal.

3 . The valves cannot all be closed. There is leakage. There is no way to establish a gas dome.

4 . Some valves cannot be closed. There is leakage.

5 . A valve closing is slowly.

Possible Reason

1 . Check the gas dome pressure to see if it is too low.

2 . Check the valve coil connection and coil

3 ( 1 ) . Y-valve. Some valves for the same gas dome are leaking, thus causing leakage for all the valves.

3 ( 2 ) . Z-valve. The valve inlet and blowing muzzle are installed backwards.

4 . There is some dirt or debris on the membrane, ii is blocking the moving iron core.

5 . The membrane orifice is blocked.

Troubleshooting

1 . Check the leakage

2 . Replace the accessories

3 ( 1 ) . Check the leakage

3 ( 2 ) . Re-install

4 . Clean the membrane and check that the membrane is complete. Check the moving iron core and air lock.

5 . Dredge the membrane orifice

During use period

Failure phenomena

1 . Some valves are leaking. The membrane cannot close tightly and the valve is always open a

little.

2 . Coil is hot and burned out.

3 . Voltage exists but the valve does not operate.

4 . Ambient temperature is below -20℃. The valve is leaking and cannot open.

Possible Reason

1 . There is some dirt or debris on the membrane, the leading part is damaged. Moving iron core is blocked.

2 . It has been turned on for too long.

3 . Membrane is damaged and the orifice is blocked.

4 . Ambient temperature is too low and here is frost in the valve.

Troubleshooting

1 . Clean the membrane and check that the membrane piece is complete. Check the moving iron core and the air lock. Replace the accessories if necessary.

2 . Check the working condition of the control system.

3 . Replace the accessories in time.

4 . Pay attention to insulation and maintaining proper temperatures.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!