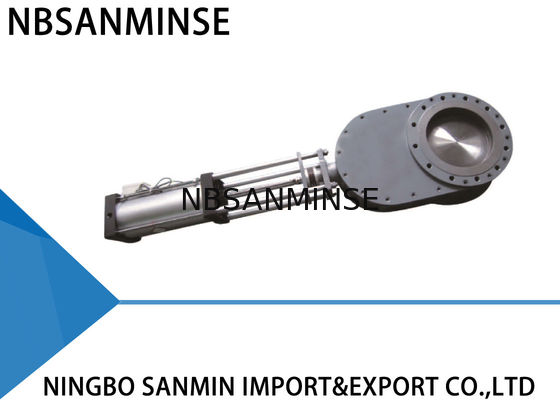

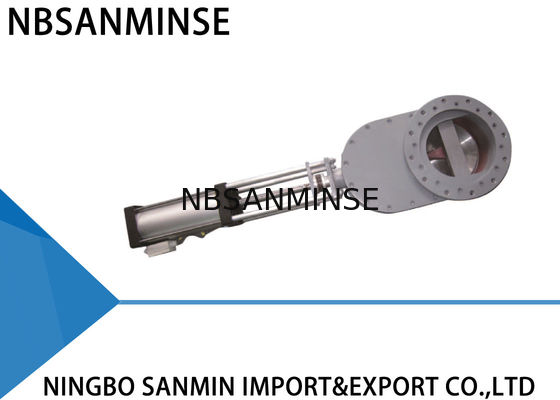

SMWZ644 ( 1 ) -10 ( 2 ) -DNB -JH Pneumatic Wear - proof Double Discs Valve ( Pebble coal )

Main Perfomance

Model WZ644-10Q double-disc valve uses a double -disc sealing and sealing surfaces are made from wear-resistant alloy or ceramic. The seal is 100% airtight and the valve achieves a long service life , particularly in applications . Consequently , overall system reliability is increased dramatically .

Operating Performance

When air is introduced into the upper cylinder port , the piston rod pushes the double-disc down and the valve is closed . When air is introduced into the lower cylinder port , the piston rod pushes the double-disc up and the valve is opened . Compression spring being placed between the discs and seal ring , forces the discs the discs against the seal ring , and also allow for discs vertical movement , which helps to compensate the thermal expansion and contraction of the parts and ensure an airtight seal under all conditions . When actuating the valve , the double-disc rotates to lap and polish the sealing surfaces . When product flows through the valve , any material entering the inner chamber is removed by vortex flow action . Hence , the valve is self-cleaning . Additional air purging can be provided to ensure clean-in-place performance . All these characteristics guarantee a long service lofe for the valve and increase the reliability of your system .

Applications

Any dust , powder , and granular products in coal-fired power plants , smelters , iron and steel plants , pharmaceutical and chemical industries .

Technical Parameters

Maximum-Operating Pressure : 1.0MPa

Maximum Test Pressure : 1.5MPa

Operating Temperature : <200℃

Leakage Test Pressure : 1.1MPa

Installation and Application

1. Prior to installation , make sure the pneumatic actuator is free of any defects like breakage and concave .

2. Make sure the joint flange , structural length , maximum operating pressure and nominal diameter are accorded with requirements .

3. During installation , not allowed to readjust studs and nuts that have been fastened originally . Align the center of two pipelines and valve diameter to be coaxial . Keep the flange surface flat . Uniformly apply force to tighten the bolt .

4. After installation , introduce air from the upper and lower cylinder ports to see whether the valve can be normally opened or closed .

5. Cheek the control switch ( if existing ) to see whether it is reliably fastened , whether its parameter is accorded with access power source , and whether it can correctly work under full opening and full closing conditions .

Troubleshooting Method

| Troubles |

Cause |

Troubleshooting Method |

| Leakage in sealing surface |

Dirt between disc and sealing surface |

Remove the dirt |

| Damage to seal ring pairs |

Repair or replace |

| Leakage in flange joint |

The bolt is unevenly screwed |

Evenly screw the bolt |

| Damage to the flange surface |

Repair the flange surface |

| Damage to the spacer |

Replace the spacer |

| Valve fails to be correctly opened or closed |

Dust deposit |

Remove dust regularly |

| Insufficient air pressure , severe leakage |

Repair air supply pipeline |

| Pneumatic components have been aged and lost efficlency |

Replace the damaged components |

| Leakage of stuffing box |

The stuffing has been aged and severely worn |

Replace the stuffing |

Installation dimension , outline drawing

| Model (A series) |

DN |

L |

d |

K |

D |

H |

n-M |

2-A |

| WZ644-10Q-40 |

40 |

120 |

84 |

110 |

150 |

443 |

4-M16 |

2-G1/4 |

| WZ644-10Q-50 |

50 |

120 |

99 |

125 |

165 |

463 |

4-M16 |

2-G1/4 |

| WZ644-10Q-65 |

65 |

120 |

118 |

145 |

180 |

528 |

4-M16 |

2-G1/4 |

| WZ644-10Q-80 |

80 |

120 |

132 |

160 |

195 |

558 |

8-M16 |

2-G1/4 |

| WZ644-10Q-100 |

100 |

120 |

156 |

180 |

215 |

601 |

8-M16 |

2-G1/4 |

| WZ644-10Q-125 |

125 |

160 |

184 |

210 |

250 |

730 |

8-M16 |

2-G3/8 |

| WZ644-10Q-150 |

150 |

160 |

211 |

240 |

285 |

798 |

8-M16 |

2-G3/8 |

| WZ644-10Q-175 |

175 |

160 |

241 |

270 |

315 |

894 |

8-M16 |

2-G3/8 |

| WZ644-10Q-200 |

200 |

160 |

266 |

295 |

340 |

958 |

8-M16 |

2-G1/2 |

| WZ644-10Q-225 |

225 |

160 |

294 |

325 |

370 |

1028 |

12-M20 |

2-G1/2 |

Main Parts and Materials

| Item |

Name |

Material |

Item |

Name |

Material |

| 1 |

Valve body |

Ductile iron |

5 |

Connecting T-piece |

Cast steel |

| 2 |

Side valve body |

Ductile iron |

6 |

End cap |

45#Steel |

| 3 |

Sealing ring |

Carbon steel + special alloy |

7 |

Linking neck |

Hodular cast iron |

| 4 |

Dise |

Carbon steel + special alloy |

8 |

Pneumatic actuator aluminum |

Aluminum cylinder |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!